Carbon dioxide capture and utilisation group

We are mainly focused on the fields of capturing and utilising carbon dioxide waste emitted from energy-intensive industries.

Our research interests include:

- Electrochemical conversion of CO2 to produce value-added products

- Electro-catalysts design and development

- CO2 capture techniques and process integration

- Electrode structure design and optimisation

- CO2 electrolyser development and optimisation

- Industrial carbon footprint mapping and modelling

- Techno-economic feasibility analysis for CO2 capture and utilisation technologies.

Facilities

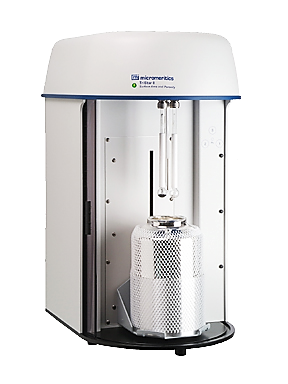

7. Surface Area and Porosity System TriStar – Micromeritics

It is a fully automated, three-station surface area and porosity analyser that deliver high-quality data. It also provides higher accuracy and speed of quality control analyses, yet has resolution and data reduction capability. It also features a Krypton Option, allowing measurements in a low surface area range. The key features include:

It is a fully automated, three-station surface area and porosity analyser that deliver high-quality data. It also provides higher accuracy and speed of quality control analyses, yet has resolution and data reduction capability. It also features a Krypton Option, allowing measurements in a low surface area range. The key features include:

- The three analysis port can operate independently of each other as well as simultaneously, gathering three BET surface area measurements in less than 20 minutes

- It accommodates the use of CO2, Ar and other non-corrosive gases such as methane, butane, or other light hydrocarbons

- Standard nitrogen system can measure surface areas as low as 0.01 m2/g. While, a Krypton Option can extend the surface area measurements to as low as 0.001 m2/g

- Can measure, calculate, or manually enter free space, accommodating special sample types and emphasizing speed when required without requiring Helium

- A 2.75-liter dewar and extended length sample tubes enables complete adsorption and desorption isotherms to be collected without operator intervention

- Can collect up to 1000 data points. Fine details of the isotherm can be observed and recorded providing high resolution and revealing pore structure details

- Removal of atmospheric contaminants from the surface and pores of a sample prior to analysis can be accomplished with optional sample preparation devices that combine flowing gas and/or vacuum with heat