Advanced forming mechanics groups

Our primary research fields are Advanced Forming Mechanics Groups, providing fundamental and practical insight and control of highly nonlinear plastic deformation processes to produce many everyday products from sheet metal.

Our research interests include:

- Finite Element modelling techniques

- Sheet metal forming techniques includes roll forming, millipede forming, incremental sheet forming and Chain-die forming

- Elastic - plastic theory and experiments

- Digital image correlation (DIC)

- Non-linear dynamics, vibrations, controls, rolling contact, elastoplastic and wear phenomena, with applications to manufacturing, mining, railway, spacecraft and biomedical systems

Experimental facilities

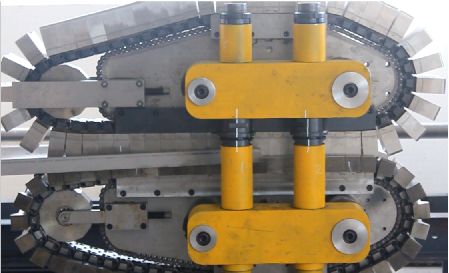

3. Chain-die former

Chain-die forming is a new sheet metal forming technology which has been developed as a supplement to roll forming in fabricating Advanced High-Strength Steel (AHSS) products. It has an advantage by reducing redundant plastic deformation during the forming process.

The implementation is achieved through increasing the deformation length, via increasing the virtual roll radii. The rolls with large radii are assemblies of shaped die-blocks through chains and therefore it is called “Chain-die Forming”.