Advanced forming mechanics groups

Our primary research fields are Advanced Forming Mechanics Groups, providing fundamental and practical insight and control of highly nonlinear plastic deformation processes to produce many everyday products from sheet metal.

Our research interests include:

- Finite Element modelling techniques

- Sheet metal forming techniques includes roll forming, millipede forming, incremental sheet forming and Chain-die forming

- Elastic - plastic theory and experiments

- Digital image correlation (DIC)

- Non-linear dynamics, vibrations, controls, rolling contact, elastoplastic and wear phenomena, with applications to manufacturing, mining, railway, spacecraft and biomedical systems

Experimental facilities

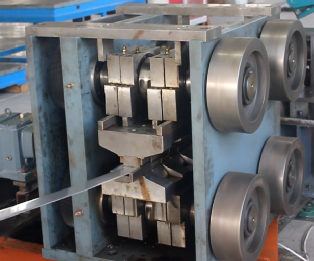

2. Millipede former

Millipede forming is an alternative sheet forming method to roll forming. It was first invented to overcome product defects that are difficult to be solved by roll forming. The concept of Millipede Forming is to manipulate a strip pass through an optimal strip’s surface defined as a transitional surface. The transitional surface is defined as the mid-surface of the strip form entry to exit positions of a forming stand.

In Millipede Forming, a flat strip is bent into a final profiled product through the specifically designed transitional passes by continuous forming steps. The strip is gradually deformed by passing the optimized transitional surface leading to minimized longitudinal strains, which is the main cause of product defects in roll forming like the edge wave, end flare, sweep or camber.