Low carbon energy and materials

Methane pyrolysis for hydrogen production

Development of an innovative and sustainable technology to utilise methane for hydrogen production as both a chemical feedstock and a clean source of energy, is a priority research area for the UQ Dow Centre.

Development of an innovative and sustainable technology to utilise methane for hydrogen production as both a chemical feedstock and a clean source of energy, is a priority research area for the UQ Dow Centre.

Our researchers are advancing new processes that produce hydrogen and/or syngas by pyrolysing methane in molten salts and metals. The intended impact is a suite of future fuels, chemicals and solid carbons which can be produced without contributing to greenhouse gas emissions.

Key people: Simon Smart, Chris Greig, Rijia Lin, Mojgan Tabatabaei, Taiwo Odedairo

For more information, please contact: Associate Professor Simon Smart

Dry reforming of natural gas in molten metal and salt systems

This project complements the typical UQ Dow Centre perspective on CO2 emissions of using innovative chemistry and process routes to avoid the production of CO2, and instead focuses on how to use innovative chemistry to utilise CO2 with natural gas to produce syngas.

This project complements the typical UQ Dow Centre perspective on CO2 emissions of using innovative chemistry and process routes to avoid the production of CO2, and instead focuses on how to use innovative chemistry to utilise CO2 with natural gas to produce syngas.

Key people: Simon Smart, Chris Greig, Mojgan Tabatabaei, Taiwo Odedairo, Rijia Lin,

For more information, please contact: Associate Professor Simon Smart

Low-CO2 production of iron

Iron and steel production is the largest energy consuming industry in the world and one of the largest CO2 emitting industries, producing around 5% of the world’s greenhouse gas emissions.

Iron and steel production is the largest energy consuming industry in the world and one of the largest CO2 emitting industries, producing around 5% of the world’s greenhouse gas emissions.

The UQ Dow Centre is developing a new process for iron ore reduction utilising innovative chemistry, natural gas and molten salts. The process yields solid iron, solid carbon and no CO2.

The intended impact is a next generation steel making process which does not generate greenhouse gas emissions.

Key people: Simon Smart, Chris Greig, Mojgan Tabatabaei, Taiwo Odedairo, Rijia Lin,

For more information, please contact: Associate Professor Simon Smart

Low-CO2 production of cement

The global cement industry accounts for approximately 7% of overall Greenhouse Gas emissions. This research examines process options designed to avoid a significant portion of CO2 emissions.

The global cement industry accounts for approximately 7% of overall Greenhouse Gas emissions. This research examines process options designed to avoid a significant portion of CO2 emissions.

This project will provide an understanding of how different regions compare on an energy and CO2 emission intensity basis, highlighting the gap between worldwide best practice and the CO2 targets for the cement industry.

Key people: Simon Smart, Chris Greig, Mojgan Tabatabaei, Mark Hodgson

For more information, please contact: Associate Professor Simon Smart

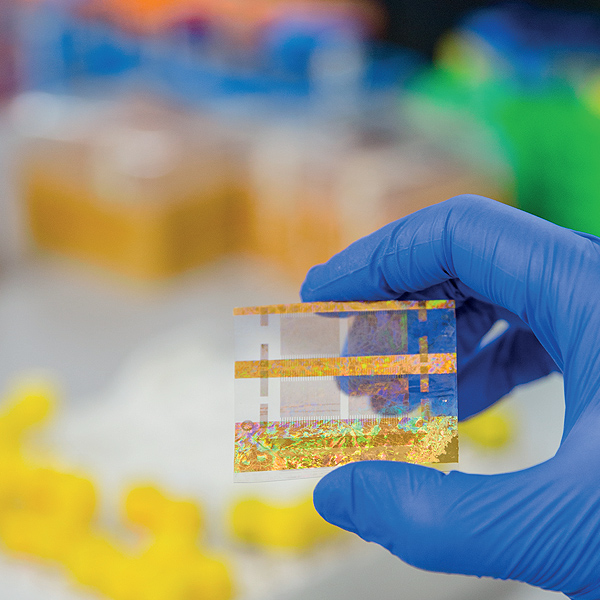

Flexible printed batteries CRC-P

A collaboration with UQ’s AIBN, UNSW and Printed Energy Pty Ltd under the CRC-P, this project aims to develop and commercialise thin flexible printed batteries.

A collaboration with UQ’s AIBN, UNSW and Printed Energy Pty Ltd under the CRC-P, this project aims to develop and commercialise thin flexible printed batteries.

These batteries will have the ability to revolutionize the powering of products such as disposable healthcare devices, sensors and wearable electronic devices. The batteries will ultimately be printed in a roll-to-roll process like a newspaper, providing significant flexibility in the way they can be incorporated into every day products.

Key people: Lianzhou Wang, Chris Greig, Jannie Grové, Miaoqiang Lyu, Songcan Wang, Yuxiang Hu, Benoit Clement

For more information, please contact: Professor Lianzhou Wang

Next-generation fertilisers

A collaborative project with UQ’s School of Agriculture and Food Sciences along with the Queensland Government and industry to improve the efficiency of fertiliser use in agriculture.

A collaborative project with UQ’s School of Agriculture and Food Sciences along with the Queensland Government and industry to improve the efficiency of fertiliser use in agriculture.

The project is using materials science and microbiology in an effort to reduce land degradation and nutrient run-off from fertilisers. These issues are significant for agricultural productivity and ocean health worldwide including in Queensland where the health of the Great Barrier Reef is at stake.

Key people: Bronwyn Laycock, Steven Pratt, Susanne Schmidt, Damien Batstone, Paul Luckman, Luigi Vandi, Torsten Witt, Nicole Robinson

For more information, please contact: Associate Professor Bronwyn