Pyrometallurgy lab

UQ's Pyrometallurgy Lab contains 25 high-temperature furnaces (up to 1650°C with +/-1°C accuracy) for heat treatment, phase equilibria and slag viscosity studies.

A vertical tube furnace is used for high temperature equilibration experiments. The furnace temperature is controlled within ±1 K by an alumina-shielded Pt/Pt-Rh 13% thermocouple placed immediately adjacent to the sample, and is periodically calibrated against a standard thermocouple.

The gas atmosphere is maintained by mixture of pure gases (such as CO, CO2 & SO2). The required gas flow-rates are maintained with the U-tube capillary flow-meters. The actual oxygen potential of gas mixture is confirmed by a DS-type oxygen probe.

The know-how of the Centre is the substrate technique. Experiments are performed on substrates made of primary phase – this prevents sample contamination from crucible material, such as MgO, Al2O3.

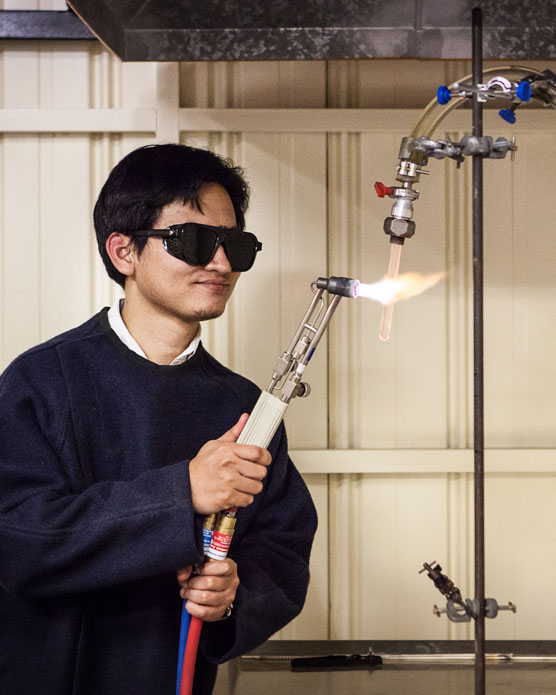

An in-house ampoule sealing facility is available for experiments in a closed-system.